1929 Miss Daytona Hydroplane from John Van Osdol on Vimeo.

Bruce Meyer purchased this vintage 17′ hydroplane race boat and flies to Bay City, Michigan to let it loose on the Saginaw River before transporting it to its next home in California

1929 Miss Daytona Hydroplane from John Van Osdol on Vimeo.

Bruce Meyer purchased this vintage 17′ hydroplane race boat and flies to Bay City, Michigan to let it loose on the Saginaw River before transporting it to its next home in California

Hi Phil,

I found your website while researching a vintage Neal Hydroplane that we recently acquired – please see attached for photos. This came from a home in Fairmont, WV and came with a racing trophy from the 50s. Does anyone know if there is a market for this? If so, would you have any advice on a value or the best place to list it for sale? Any feedback would be much appreciated!

Thanks for your time,

Christa

blackdogsalvage.com

(540) 206-3269 direct

(540) 343-6200 main

Tune in to Salvage Dawgs, featuring Black Dog Salvage, on the DIY Network…. new episodes begin airing June 1st!

Find us on facebook: www.facebook.com/blackdogsalvage

When you have a moment, surf over to Phil Kunz Photography and check out the latest update he has made to his website. They are the point summary sheet totals for the MACH Series. Almost 30 years worth of points you can pour over. Check it out!

Vintage hydros ready to go in on Eastwood Lake in Dayton. The weather was perfect – slight wind and temps in the mid 60s made for a spectacular setting. This is the first time in many years that Dayton had 2 cranes available to move the boats in & out of the water faster.

Roughly 33 boats were in attendance with 13 being vintage. All ready to test & tune.

Roughly 33 boats were in attendance with 13 being vintage. All ready to test & tune.

The long distance didn’t stop vintage owners from traveling many miles to have a chance to run the famed Hydrobowl course.

The long distance didn’t stop vintage owners from traveling many miles to have a chance to run the famed Hydrobowl course.

Back to front – Tijuana Taxi – Jay Marshall of Baton Rouge, LA.

Chuck Wagon – Steve Wace owner, with his son Ross driving, from Brockville, Ontario.

Speculation – New owner Kester Hamilton from Ottawa, Ontario with Bob Bramlage driving .

— The oldest and newest boats at Dayton this year —

— The oldest and newest boats at Dayton this year —

The Barracuda with owner Tim Settle sitting on his 1947 Wickens built hydro.

On the crane — is the brand new Old Crow being put in the water for the very first time. The Old Crow is a Stadaucher design, built by Mr. Miller and owned by Andrew Christopher and Brent Schultz. This National Modified was put to the test by driver Dan Kanfoush and made some very fast runs this weekend.

Here’s a neat video showing the tear down and prep work for the rebirth of Scrappy by members of the California Speedboat Association. After a minute or 2 of the photo slide show that starts off, a time-lapse video takes over as the CSA members kick into gear, tear her apart and get her ready for new lumber.

Over at Phil Kunz Photography (in case you haven’t visited the “Updates to the website” section) We have all new photos opening up and scrolling across the home page.

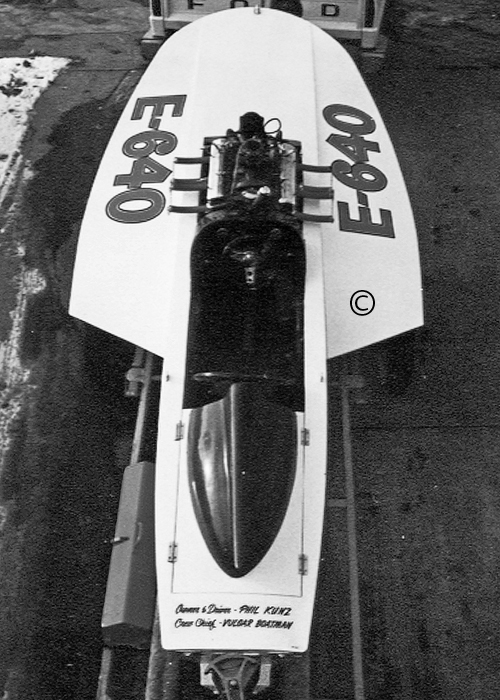

In the Scrapbook section, there is almost 500 new ‘old’ photographs now posted. As you view all the boats in the Scrapbook, wherever possible, one can read the boat name, number, owner, driver, race site the photograph was taken and year. And NEW this year — we added the builder’s name for all the boats you see. Enjoy.

Adding all the boat builder’s name was an interesting delight. In the course of a few evenings, Phil would be telling me who built what boat and I was typing furiously as we went through each boat, one-by-one. Amazing the memory this man has. This all would have gone quicker, but most boats have a story and Phil and I would get sidetracked often as his stories veered us away from the task at hand.

I was amazed at the number of boats that were either “Homemade built” or built from “xxxx plans”. Ya know, when I think about it, it is quite interesting (historically speaking), back then – how many inboard hydros were built by their owners and/or friends, jack a motor somewhere, tear it down, hot rod it out….and show up at a boat race ready to kick some ass. Maybe the boat sanctioning organizations, today could take a page from this and try to inject some classes that have this flavor. But on the other hand – maybe there is not enough young folks these days that would take on the challenge of building your own inboard hydro, trips to the junkyard or speedshop, steal a motor from something, build a trailer, find some used tires for it, etc…..then hope to have some cash leftover to drag it to all the races during the summer.

Completely restored from the ground up… Phil Kunz’s vintage 280 hydro, Helter Skelter and Jack Hines’ vintage 266, Miss Peg sparkle and gleam under the lights at the Toys For Kid’s Charity Race Car Show at Lang’s Chevrolet on Sat 16 Mar and Sun 17 Mar 2013. They drew a lot of attention. Brings back a lot of good memories seeing these wonderful hydroplanes. The best of the best is watching them doing an exhibition run on the race course. The mighty sound of the engines send chills up your spine and stands the hairs up on the back of the neck. Yeah! Too cool!

Phil posted these pictures in Facebook.

Sprint cars, midgets, late models, modifieds, stock cars, legend cars, dwarf cars, go karts, drag cars, compacts, vintage race cars were on display as well. I especially enjoyed the vintage race cars. It was a great show.

My wife is downstairs watching the Academy Awards, which brings up a thought about hydroplanes and movies. Here’s some movies that I know of that had inboard hydroplanes featured in them. If there were any others, let me know.

“Racing Fever – The Movie” brings forth the following movie trailer. If you haven’t bought and seen this 1964 movie yet, buy it and get ready to see a really ‘bad movie’ with the most stupidest, love story / bad guy storyline plot. It’s so stupid, you’ll laugh more than anything, but in the 60s, if would have probably been a movie one would typically walk out on, if it were not for the neat action footage of the old limited class hydroplanes doing their thing in Florida.

Magnificent Obsession (1954) trailer

starring Rock Hudson & Jane Wyman

I believe this has the unlimited boat, Hurricane which Rock Hudson’s playboy character owns and uses for one of his play toys.

Madison – Movie Trailer (long version)

Route 66

The famous TV show. This 1963 episode feature the 4-seater Miss Budweiser Unlimited hydro (Bernie Little converted it to drove folks around in) going in a head-to-head “race” with Ray Gassner’s Sunshine Baby IV, H-57 7-litre Lauterbach. Guy Lombardo makes a few appearances and his Port-O-Call Lounge, too.

Thanks to Brent McLean for sending in the video link

……..and Guido Romani send me this about an Italian movie that featured hydroplanes: Violenza sul Lago (about 1952/3) with Mario Verga boat “Laura” and a few passages with driver/owners Verga and Selva as actors!

Guido states video will be available later – but below appears to be the movie poster.